News

News

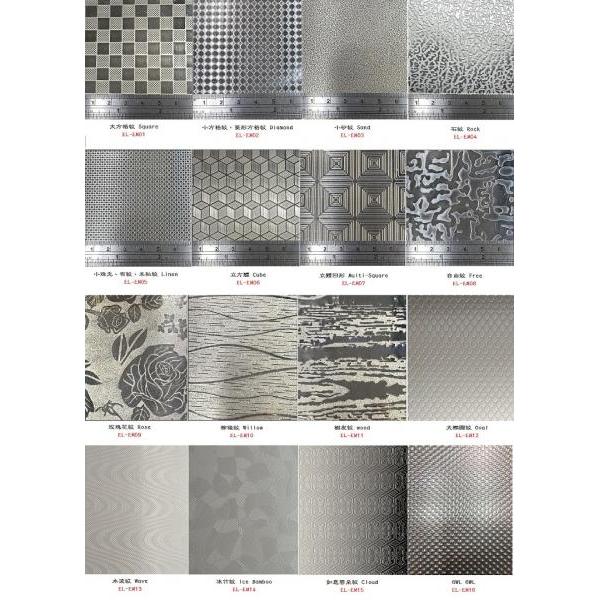

Film: 3D EMBOSSED: WAVE - FREEDOM PATTERN

SALE: 304 2B/BA COILS STOCK LIST

FACTORY:TANG ENG IRON WORKS CO.,LTD

ORIGIN:TAIWAN

PACKING:STANDARD EXPORT PACKING

PRIME QUALITY FOR GENERAL APPLICATION

STANDARD:ASTM A240/A480,EN1008-2

304 COIL STOCK LIST

Stainless & Special Steel News~ Stalatube installs a new high warehouse at Lahti plant

3/16/2009

Stalatube announced that it has taken in to use the new high warehouse for finished products next to their factory in Lahti in the beginning of 2009. This investment is a first part of bigger entity.

Besides this new high warehouse, new stainless steel coil slitting line under the new roof and warehouse for raw material coils are also part of the investment. As a whole this investment worth of over EUR 7 million is the biggest investment in Stalatube history. New slitting line, which will work at the full speed already next summer 2009, is able to cut even 8 mm thick stainless steel coils to strips and to handle nearly 30 tonnes heavy mother coils.

Target of this investment is to fasten throughput times and to increase customer based flexibility. At the same time it is possible to improve delivery reliability, because the dependence on delivery times of raw material deliveries is getting smaller. These faster delivery times make it possible for their customers run their systems with lower stock levels and benefit on that today, when metal prices are fluctuating heavily.

Sources from: http://steelguru.com/news/index/2009/03/16/ODYzODY%3D/Stalatube_installs_a_new_high_warehouse_at_Lahti_plant.html

Stainless Steel import monitoring system extended U. S. Commerce Department decides to keep tracking trade flow into 2013

By Tom Stundza -- 3/18/2009

The Department of Commerce has extended the Steel Import Monitoring and Analysis System until March 21, 2013, according to a notice in today’s Federal Register. The program, started in February of 2003, provides a gauge of month-ahead steel imports ahead of actual delivery.

All steel imports are required to have an import license, which provides an early notice of the volume, value and type of steel products expected to enter the U.S. approximately seven weeks ahead of the expected entry date. The licensing system collects data from the steel-import permits filed with U. S. Customs. The system has proven to be a popular leading indicator with steelmakers, steel importers, trade experts and the media-- even though actual monthly tonnages often vary from the licenses, usually because of lags in delivery from offshore sources.

Authority for the system is granted on a four-year basis, but some steelmakers have suggested it become permanent. “U.S. Steel strongly supports extension (since) the system has become so useful, and is now such an accepted part of the market,” says a letter to Kelly Parkhill, director of industry support and analysis at the Commerce Department’s Import Administration. The letter also says that “Commerce should give serious consideration to making (the system) permanent.”

The steel import licensing system began when President Bush gave domestic steelmakers trade relief from a surge of imports under Section 201 of the Trade Act of 1974. The licensing regime initially was limited to semi-finished steel, hot-rolled and cold-rolled coil, rebar, plate and standard pipe. When the program was renewed in 2005, coverage was expanded to include all steel product categories, adding such products as wire rod, heavy structural beam, large-diameter pipe, oil country tubular goods (OCTG), and stainless steel sheet and strip.

Sources from: http://www.purchasing.com/article/CA6645105.html?industryid=48389

Stainless Steel-New radar level device for solids

3/19/2009

While most radar level devices can measure solids or liquids, there are specific characteristics of solids that can make the job more challenging, and this new product has those in mind.

A well-developed manufacturer introduced its Optiwave 6300 C radar level device, designed specifically for measuring the uneven surface of solids typical in silo storage. Using FMCW (frequency-modulated continuous wave) technology, the new units are optimized to measure powder, granulates, and bulk solids in buffer silos, hoppers, bulk storage containers, and on conveyor belts. Krohne expects that the design will have many uses in a variety of industries, such as mineral and mining, food, chemicals, pulp and paper, and power.

The company says the innovative drop form of the Optiwave’s plastic antenna generates a 2° beam angle, smaller than most conventional antennas. This makes an antenna aiming kit to amplify the reflected signal unnecessary. The drop form also prevents crusting or dust layers on the antenna, making it ideal for applications with dust formation, such as mineral powder and granulates or wood chips.

The Optiwave 6300 C comes with a variety of options and users can choose a 3 in. diameter (DN 80) antenna made of polypropylene (PP) or Teflon (PTFE) or a 6 in. (DN150) PP model. Conventional stainless steel horn antennas up to 6 in. (DN 150) with built-in horn purging feature are also available.

The installation wizard is specifically adapted for bulk solid measurement. Start-up is easy with help functions. A large screen with a four-button keypad makes navigation easy, and the wizard displays information in nine languages.

Sources from: http://www.controleng.com/article/CA6644159.html?industryid=48516

Stainless-steel cable tray

Plant Engineering, 3/4/2009

The expanded line of CLEAN TRAY UL Type 1 stainless-steel cable trays for power and data cable protects rated cabling and features a sloped-top sanitary design to minimize dirt, debris and mold build-up in addition to facilitating easy cleaning. The design includes numerous new sloped-top fittings, variable-angle fittings and telescopic straight sections for installation flexibility. Other standard features include removable top or side for cabling access, perforations for drainage following washdown and connecting hardware. Trays are available in sizes ranging from 2 x 2 to 6 x 6 inches.

Sources from: http://www.plantengineering.com/article/CA6641643.html?industryid=47223